How to Diagnose Fuel Pump Assembly

Finding Faulty Fuel Pumps:

Where do you begin your diagnosis, if you have an engine that cranks, but won't start?

If ignition and compression are both OK, that leaves fuel as the obvious culprit. Now the question is, what's wrong with the fuel delivery system? Well, the most likely causes are:

- A dead fuel pump (could be the pump, pump relay or wiring circuit);

- A plugged fuel filter;

- Low fuel pressure (weak pump or restricted line); or

- No pulse signal to injectors (bad injector relay or PCM driver circuit).

On most vehicles, the pump is energized by the PCM via a relay. The pump circuit also may be wired through an oil pressure switch and/or an inertia safety switch that kills the pump in case of an accident.

Other electrical problems that can affect the pump include low voltage in the pump's power supply circuit or high resistance in the pump's ground circuit. Either may prevent the pump from running or spinning fast enough to generate normal fuel pressure.

Tests For Diagnosing A Faulty Fuel Pump:

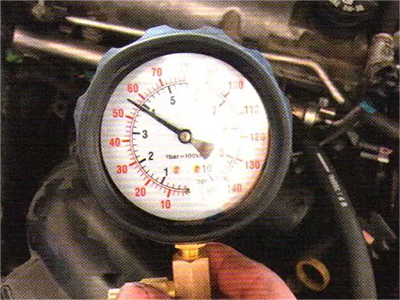

Dead Head Pressure: This checks the maximum output pressure of the fuel pump. With the return line blocked, the pump should produce a pressure that's significantly higher than its normal operating pressure at idle. If the pressure rating does not go up with the return line blocked, the pump may not be able to deliver enough fuel at higher engine speeds. Possible causes include a worn pump, low voltage at the pump, a plugged fuel filter or inlet sock in the tank, an obstructed fuel line or an almost empty fuel tank.

Fuel Volume Test: A fuel pump that delivers normal pressure may still cause drive-ability problems if it can't deliver enough fuel volume to meet the engine's needs. A fuel volume test may therefore be the best way to evaluate the pump's condition.

A fuel volume test measures the volume of fuel delivered over a specified interval. This test can be done by connecting a fuel flow gauge to the fuel supply line, or by disconnecting the fuel return line from the fuel pressure regulator and connecting a hose from the regulator to a large container.

Caution: Make sure there are no open sparks or flames nearby while doing this test!

With the engine off, energize the pump and measure the volume of fuel delivered during the specified interval of time. As a rule, a good pump should deliver about one quart of fuel in 30 seconds.

Misdiagnosis is the leading cause of fuel pump returns. If the engine runs but displays driveability symptoms that you suspect are fuel-related, attempt to eliminate possible causes by:

- Checking the vehicle's OBD system;

- Checking the ignition system;

- Checking for vacuum leaks;

- Checking the EGR & PCV systems; and

- Running a power balance test.

By diagnosing a faulty fuel pump assembly, the root cause of the problem can typically be identified. At this point, the fuel pump can be repaired or replaced. Our store offers a variety of fuel pump assemblies for you to choose from. Should you encounter any problems during installation, you can seek help on our official website, where we provide high-quality after-sales service.