Wheel spacers have easily become one of the most common add-on accessories to a four-wheel-drive. Wheel spacers are round discs that are installed between the rotors and wheels. The purpose of installing wheel spacers is to widen the offset of the wheels, which widens the vehicle's track. This has handling benefits even when the tire size does not change. While the modern wheel spacer has become commonplace, the stigma around their safety continues to remain in question.

How It Works

Wheel spacers install onto your wheel assembly. By slotting between the assembly and wheel, they create a gap that sets the wheel farther outward. This increases the space between the wheel hub assembly and the wheel itself. It's important to note that spacers don't move the hub assembly, they only move the wheel.

What Are They Made Of?

The vast majority of wheel spacers in the truck and SUV segment are comprised of aluminum. Specifically, 6061-T6 which weighs significantly less than steel and provides ample strength for its intended use.

Why Use A Spacer?

Considering that the wheels of most four-wheel drive vehicles have a high backlash from the factory, adding tires larger than stock may cause friction problems in the suspension, frame, and even body parts. Adding a wheel gap will move the tires outward from the vehicle, which can greatly help resolve clearance and friction issues. Given that gaskets are much cheaper than new wheels (and can be installed at home), they have become a popular upgrade.

Matching Stance

Another reason we see that wheel spacing is used in the truck world is to match the position of the vehicle. This is usually due to a wider track at the front of the vehicle than at the rear. This is one of the reasons why wheel spacers are usually sold in two sets instead of four.

Installation safety tips

The concern with any gasket is that it will loosen. To prevent this from happening, not only make sure to follow the recommended torque specifications, but also use thread locks on the bolts connected by the gasket bolts. High-strength thread locks are the favorite of many installers. For safety, be sure to mark the spacer nut. This will help you quickly see that they are still tight when you perform routine maintenance such as tire rotation.

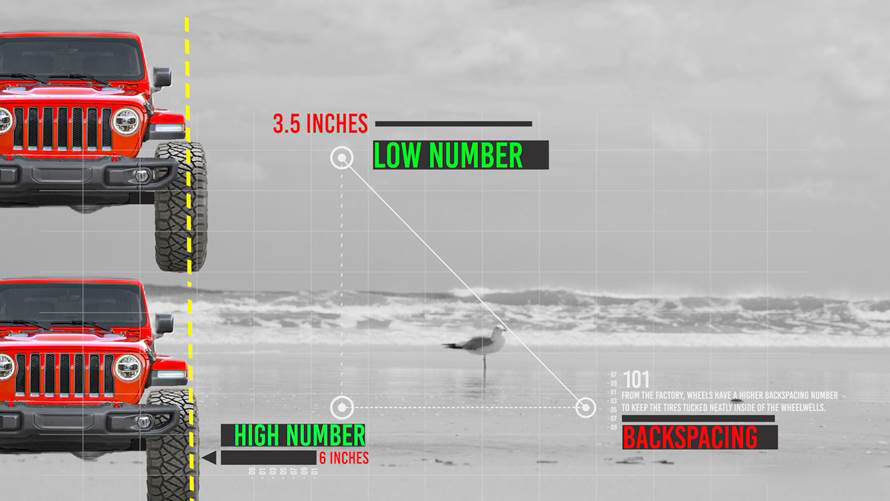

Backspacing

Adding a wheel spacer has a similar effect as swapping to a wheel with less backspacing. For example, if your spare wheel has a 6-inch rear pitch, and you add a 2-inch wheel spacer, your rear pitch number is now actually 4 inches. The lower the rear spacing number, the farther the wheels are from the vehicle. Just as you run wheels with low numeric backspace numbers (i.e. 3.5 inches), you use wheel spacers to put more pressure on the bearings and front end components of the vehicle. This is usually not a major problem when gaskets are used in combination with spare wheels, but can be a problem when used in combination with aftermarket wheel sets. While gaskets are not usually a point of failure, pushing the wheel further can cause premature failure of ball and socket joints, wheel bearings, and tie rods.

How Much Spacing?

We prefer to keep it below 2 inches when running gaskets. However, you need to be aware that some OE studs may protrude from the mounting surface of the gasket. This means you need to trim any overhangs before installing the wheels. Also, look for hub-centered gaskets where possible for the best and strongest fit. While this goes without saying, do not stack wheel gaskets.

Trail Safe

A misunderstanding worth clarifying is that the wheel spacers are just for mall crawlers and they will fail off-road. But in fact, it's not. Over the years, we have personally conducted a comprehensive test on the wheel base, and have never experienced a fault related to the wheel base. In general, shims are an economical way to keep the wheels and move them out a bit. Although we prefer to buy new wheels over running wheel spacers, spacers are a safe and affordable alternative.