Want to know how the oil pump promotes the overall health and operation of the vehicle engine? The short version is related to the need to maintain a stable oil pressure inside the motor to keep the lubricant flowing to every component, gap, and channel in the device. For this, an engine oil pump that can produce the correct psi or pounds per square inch oil pressure is needed. Think of it as the core of the engine, ensuring that the lubricant never stops flowing.

How does it get the job done? Let's break it down.

OIL PRESSURE ISN’T CONSTANT

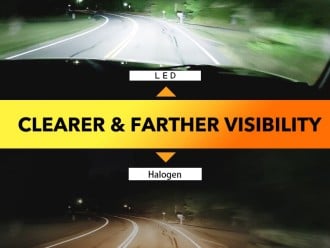

If you have ever driven a car with an accurate engine oil pump pressure gauge that tracks actual pressure, you will notice that the amount of pressure in the engine will not remain constant. This is not a design flaw-an an idling engine does not need as much pressure as an engine running at a higher speed to keep all its moving parts lubricated. Typically, 10 psi of pressure is required for every 1,000 rpm, although this number may vary with high-performance engines.

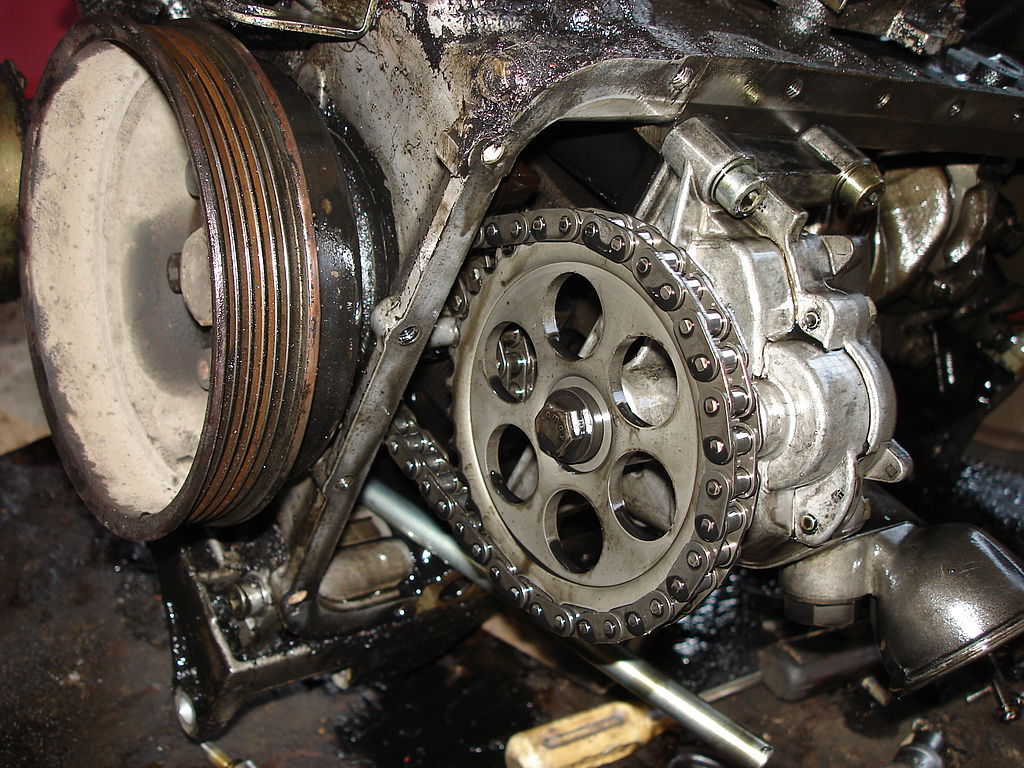

The direct relationship between oil pressure and engine speed is related to the oil pump design itself. These devices are connected to the crankshaft of the engine to obtain the drive required for operation, usually running at half crankshaft speed. The amount of pressure produced is a function of the engine speed itself.

EACH DESIGN IS DIFFERENT

Most engines run a wet oil sump oiling system, which means that the bottom of the rotating parts of the engine penetrates the oil sump and sprays the lubricating oil upwards onto the cylinder as it rotates. The oil pump is required to push the oil to the top of the motor.

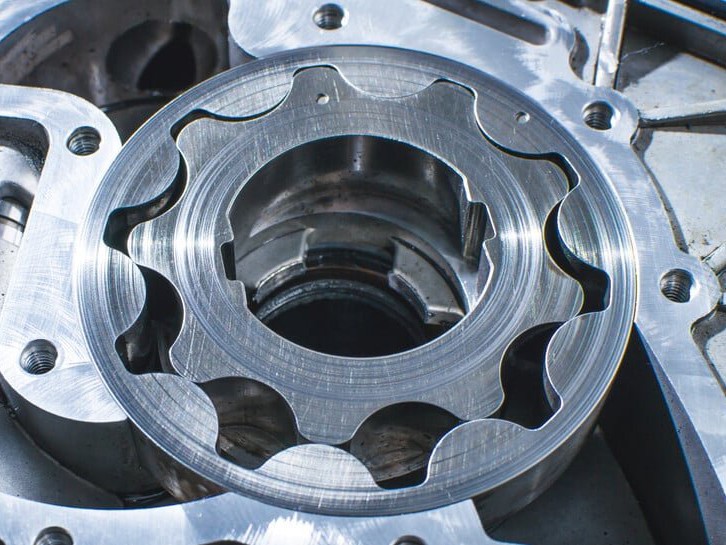

There are many pump designs, but each one revolves around the concept of a set of gears or rotors, which pressurize the oil by pressing it on the housing where the gears or rotors rotate. Gear pumps are an older design, and rotors—especially eccentric rotor designs, consisting of two rotors with more lobes on one side than the other—are more common in modern vehicles. There are also designs that use sliding vanes on the rotor, and a dry oil pan oiling system that completely eliminates the oil pan and relies on a pair of oil pumps to keep the entire rotating assembly lubricated.

Each type of pump pushes the oil through the engine's oil filter, then up through the motor to the top, and finally drips back into the oil pan again. There are also pressure valves that can be opened to ensure that the oil does not exceed a certain psi that may damage internal components.

In short, there are different pump designs in modern vehicles, but it is a necessary component for your car's engine to work properly.

Check out all the engine parts available on ECCPPAutoParts.com and trust one of our daily maintenance and repairs. For more information on the engine oil pump replacement, please consult a knowledgeable expert.